The Symbols Glossary and Appendices to this Specification are an integral part of the Specification. One addressed to the AE one for the detailer and a third.

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

The Fundamentals of Piping Design VOL 1 Shreyas Hattekar.

. Fweld weld factor. The latest Lifestyle Daily Life news tips opinion and advice from The Sydney Morning Herald covering life and relationships beauty fashion health wellbeing. Shipbuilding is the construction of ships and other floating vesselsIt normally takes place in a specialized facility known as a shipyard.

Considerations have been added for VIVVIM and tendon buckling during tendon free standing phase. Inspection Examination and Testing. Different welding techniques are used for different.

Shipbuilders also called shipwrights follow a specialized occupation that traces its roots to before recorded history. Aweld effective fillet weld area in cm 2. Research Council on Structural Connections.

Various processes involved in fabrication of the prototype model are as under. CHAPTER 24 GLASS AND GLAZING. The COTP may require that the operator of the facility notify the COTP before any welding or hot work operations are conducted.

529606 Reserved 529607 Fasteners. RCSC - Specification for Structural Joints Using ASTM A325 or. The facility operator shall ensure that the following.

Fabrication processes for bucket elevator 1. The Fundamentals of Piping Design VOL 1 Shreyas Hattekar. NEHRP Seismic Design Technical Brief No.

The principal changes incorporated in this edition of the Specification include. It is used to prepare joints for connection in the shop and on site and for the attachment of other fixtures and fittings. Weld Procedure Specifications WPS are provided.

4 produced by the NEHRP Consultants Joint Venture a partnership of the Applied Technology Council and the Consortium of Universities for Research in Earthquake Engineering for the National Institute of. Post Weld Heat Treatment PWHT requirements and procedures are also outlined. FOREWORD DNV GL rules for classification contain procedural and technical requirements related to obtaining.

Welding with equipment which performs the welding operation without adjustment of the controls by a welding. This document provides standards of practice for both the architectengi-neer AE and reinforcing steel detailer in showing reinforcing steel details. Any welding or hot work operations conducted on or at the facility must be conducted in accordance with NFPA 51B incorporated by reference.

CHAPTER 25 GYPSUM BOARD GYPSUM PANEL PRODUCTS AND PLASTER. The materialmetal weld metal carbon granular flux and so forththat backs up the joint during welding to. Chapter 18 Soils and Foundations Chapter 19 Concrete Chapter 20 Aluminum.

Shipbuilding and ship repairs both commercial and military are referred to as naval engineering. Whenever design is specifically required by the provisions of this chapter such design shall be in accordance with the requirements of this code and executed by or under the supervision of a registered design professional who shall cause his or her seal and signature to be affixed to such documents. Welding and Brazing Qualifications.

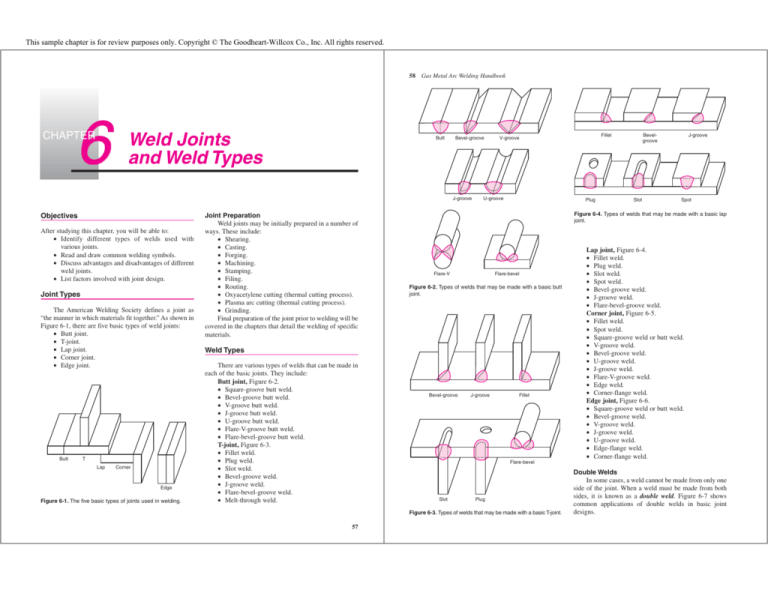

B314 and B318 allow qualification of welds through API 1104. SECTION 1 DESIGN OF WELD JOINTS Symbols For symbols not defined in this section refer to Ch1 Sec4. Classification OF Structural Stee.

A short summary of this paper. FABRICATION OF BUCKET ELEVATOR PROTOTYPE After getting the above program output for prototype model design fabrication of the model is carried out. AWS A24 - Standard Symbols for Welding Brazing and Nondestructive Examination.

AWS D11 - Structural Welding Code - Steel. Elementary Structural Problems in Steel and Timber bby Young and Morrison 3d Edition john Wiley and Sons All purpose carton stel A 36 4 529 These steels centains 17 Carbon 15 Manganese 060 Silicon and 060 Copper. Welding is a core activity in the fabrication factory undertaken by skilled qualified operatives working to a welding quality management system under the control of a Responsible Welding Coordinator.

Better definition of tendon design principal Gu idance note has been added to explain fail proof. The Fundamentals of Piping Design VOL 1 Download. Fyd coefficient dependent on the material strength of the.

Design of Modem Steel Structures by Linton E. Download Full PDF Package. 22 Full PDFs related to this paper.

Grinter Macmillan Company 16. B Each new aircraft fabrication method shall be substantiated by a test program. It is divided into three parts.

If a fabrication process such as gluing spot welding or heat-treating requires close control to reach this objective the process shall be performed according to an approved process specification. F root face in mm. ASTM A992 - Standard Specification for Steel for Structural Shapes.

Removal of previous clause 389 on settlement or subsidence. Considerationsguidance notes for tendon fabrication have been added. The equipment may or may not perform the loading and unloading of the work.

Welding of Pipelines and Related Equipment or ASME Section IX. A non-mandatory Commentary has been prepared to provide background for the Specification provisions and the user is encouraged to consult it. CHAPTER 18 SOILS AND FOUNDATIONS.

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

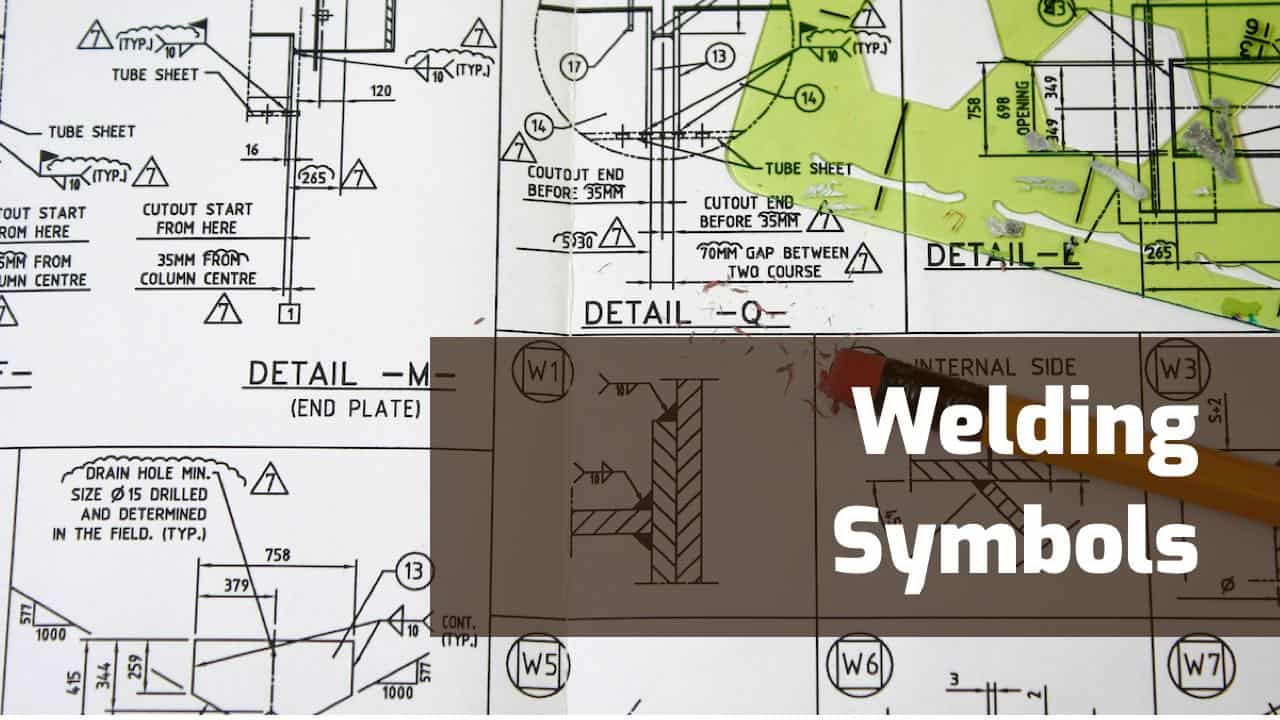

Weld Symbol Dimensioning Welding Projects Welding Training Welding

Welding Joint Design And Welding Symbols Ppt Video Online Download

0 comments

Post a Comment